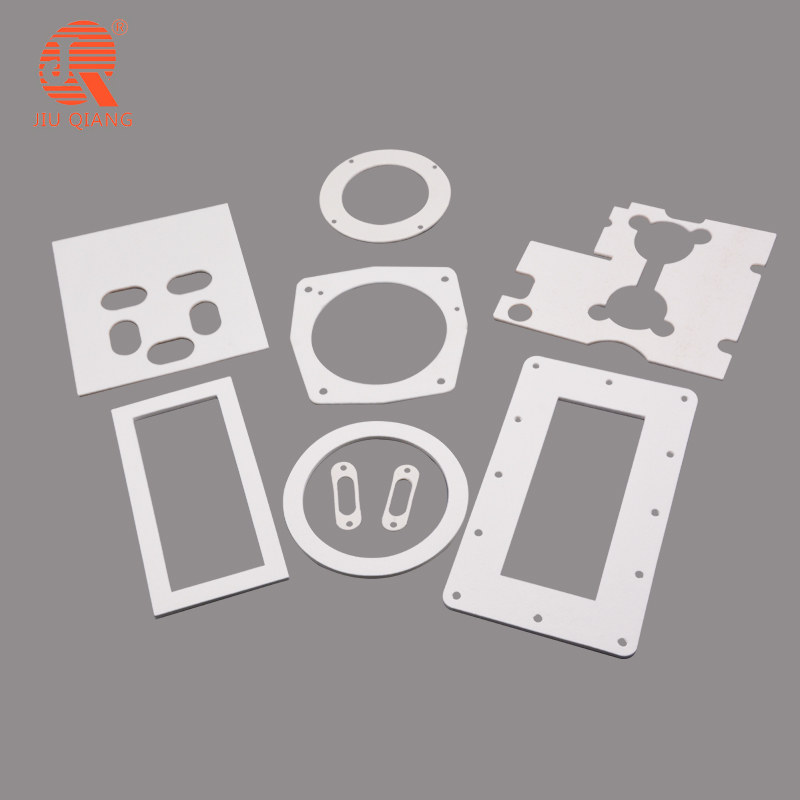

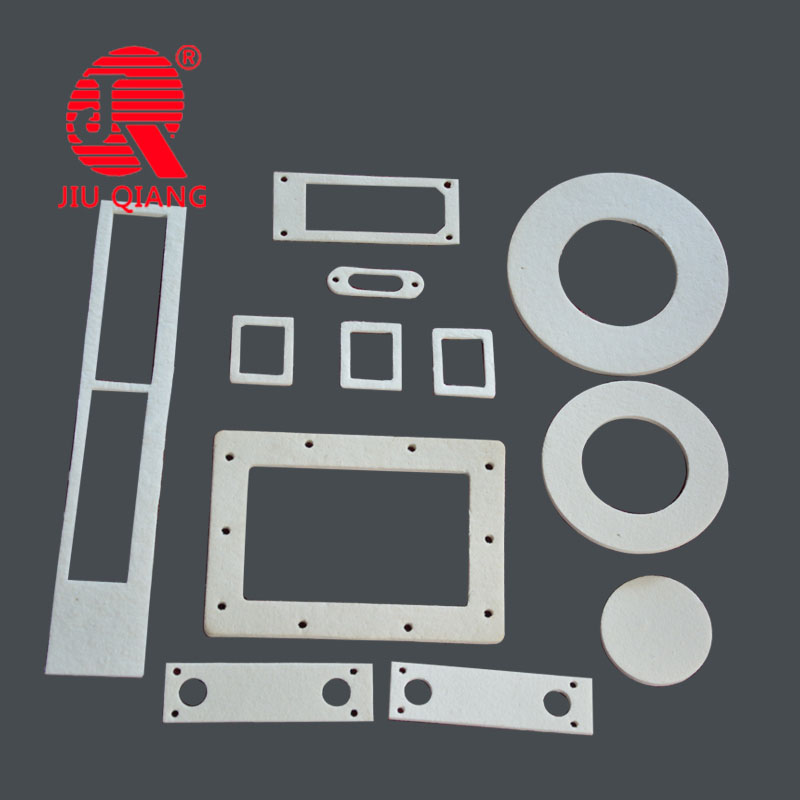

Mocheso o Phahameng oa Thermal Insulation Ceramic Fiber Gasket

Mefuta e fapaneng e ka sebetsoa ho latela litlhoko tsa bareki.

● Tlanya Likhoune tsa Hole.

● Mabokoana a Riser.

● Mabokoana a Riser.

● Lesela la ladle.

● Ho Tšela Likopi.

molemo

Molemo oa sebopeho sa fiber ea ceramic

1. Ho fokotsa mocheso oa mocheso le ho boloka mocheso o tlaase.

2. Matla a compress a phahameng.

3. Ho bonolo ho kenya.

4. Ho tsitsisa mocheso o babatsehang le ho hanyetsa mocheso oa mocheso.

5. Sebaka se boreleli.

Ho se hloeke ho fokolang, le palo e tloaelehileng ea bongata ba bongata le botenya.

Matla a maholo a mochine le matla a sebopeho.

kopo

Tšebeliso ea sebopeho sa fiber ea ceramic

1. Indasteri sebōpi lera lera le bricking-up insulating lera.

2. Lisebelisoa tsa ho futhumatsa mocheso bakeng sa mocheso o phahameng le thepa ea mocheso o phahameng.

3. Ho futhumatsa mocheso, ho thibela mollo, ho pata molumo le lisebelisoa tsa motlakase bakeng sa indasteri ea lifofane le ea ho haha likepe.

4. Mocheso o phahameng oa sebōpi, koloi ea sebōpi, li-baffles tsa mamati le lisebelisoa tsa ho arola.

Leqephe la lintlha

| Kereiti | Standard | Aluminium e phahameng | Zirconium | ||

| Mocheso oa Mokhahlelo(℃) | 1260 ℃ | 1300 | 1430 | ||

| Mocheso oa Mosebetsi (℃) | 1150 ℃ | 1260 | 1400 | ||

| Boima ba 'mele (kg/m3) | 300-450KG/M3 | ||||

| Thermal conductivity by mean temp.(w/mk)(Boima ba 285kg/m3) | 0.085 (400℃) 0.132 (800℃) 0.180 (1000℃) | ||||

| Compress Strength (Mpa) | 0.5 | ||||

| Ho thatafala | E ntle e thata | ||||

| Apara Resistance | Ba bang | ||||

| Lik'hemik'haleSebopeho | AL2O3 | 42-43 | 52-55 | 32-33 | |

| AL2O3+SIO2 | 97 | 99 | -- | ||

| ZrO2 | -- | -- | 15-17 | ||

| Fe2O3 | <1.0 | 0.2 | 0.2 | ||

| Na2O+K2O | ≤0.5 | 0.2 | 0.2 | ||

| Maikutlo: Lintlha tse ka holimo ke tsa litšupiso.The Max.temp.ho itšetlehile ka maemo a mosebetsi. | |||||

Liphutheloana tsa sebopeho sa fiber ea ceramic

1. Lebokose le mokotla oa polasetiki ka hare.

2. Pallet, bakeng sa ho nahana ka mojaro le ho laolla.